A mechanical seal is a device used to contain the gas within the stationary compressor casing where the rotating shaft passes through. Thus, keeping the gas from escaping into the environment.

If you’re thinking about purchasing a gas compressor from Ro-Flo for your application, you’ve likely noticed that there are two options for the shaft seals: single face mechanical or double bellows. Single face mechanical seals are valued for their simple, robust design that is easily repaired in the field, while double bellows seals offer a second level of protection. Here is an explanation of the differences between single and double bellows mechanical seals and the best applications for each type.

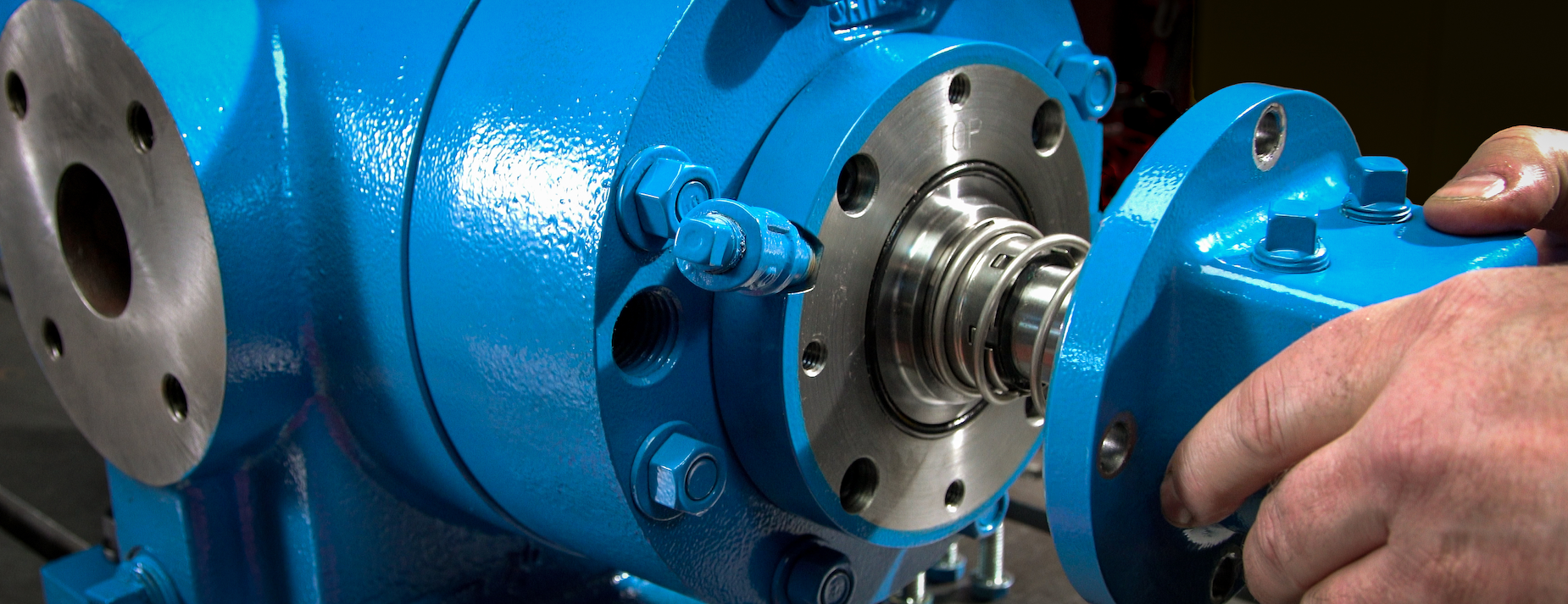

Single Face Mechanical Seals

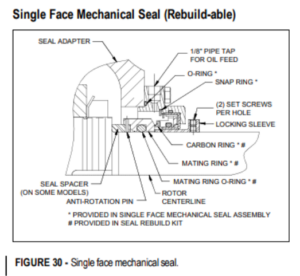

While the concept of a seal is straightforward, in operation inside a rotary sliding vane compressor, the execution is more complex. Single face mechanical seals utilize a spring to press together two flat surfaces (faces), which slide against each other. Lubricating oil is injected into the seal housing to cool and lubricate the seal’s internals. The lubricating oil forms into a thin film between the sealing faces, creating a barrier between the process gas and the atmosphere.

utilize a spring to press together two flat surfaces (faces), which slide against each other. Lubricating oil is injected into the seal housing to cool and lubricate the seal’s internals. The lubricating oil forms into a thin film between the sealing faces, creating a barrier between the process gas and the atmosphere.

To keep your single face mechanical seal operating properly, be sure:

- The seal is receiving the proper quality and quantity of lubricating oil

- There is no debris being introduced to the sealing faces

- The sealing faces and/or o-rings aren’t damaged during installation

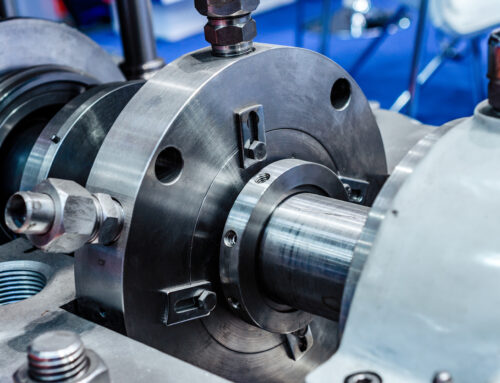

Double Bellows Mechanical Seals

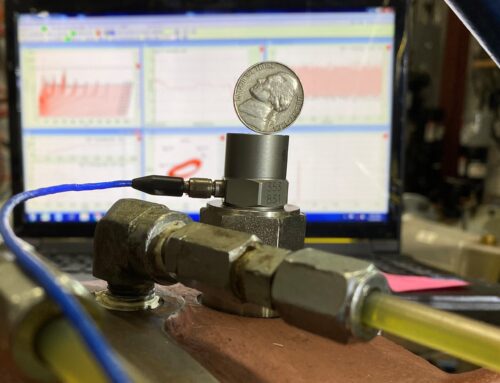

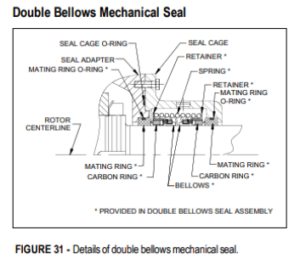

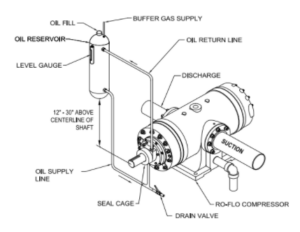

This type of seal has two sets of contact faces. The two sets of faces are back-to-back, or dual-opposed, separated by a coil spring, thus pushing in opposite directions. The double bellows mechanical seal requires a lube oil support system. The support system is designed to keep the seal parts submerged in oil and to maintain pressure on this oil system that is greater than the pressure inside the compressor. With this pressurized system, if leakage occurs at the outer seal, it will be towards the atmosphere and air will not be drawn into the compressor. If leakage occurs at the inner seal, lube oil will be pushed into the compressor. Either of these leakages will be detected with a pressure sensor on the oil support system, so the compressor can be shut down prior to any gas leaking to the atmosphere. Details of the required lube oil support system can be found in Ro-Flo’s Installation, Operation and Maintenance Manual.

The double bellows mechanical seal requires a lube oil support system. The support system is designed to keep the seal parts submerged in oil and to maintain pressure on this oil system that is greater than the pressure inside the compressor. With this pressurized system, if leakage occurs at the outer seal, it will be towards the atmosphere and air will not be drawn into the compressor. If leakage occurs at the inner seal, lube oil will be pushed into the compressor. Either of these leakages will be detected with a pressure sensor on the oil support system, so the compressor can be shut down prior to any gas leaking to the atmosphere. Details of the required lube oil support system can be found in Ro-Flo’s Installation, Operation and Maintenance Manual.

It is important to note that the lube oil support system must be pressurized prior to pressurizing the compressor or gas piping system – whether for pressure testing or compressor operation. If the process gas system is pressurized prior to the support system being pressurized, the seal is likely to fail.

Double bellows mechanical seals are used for any application in which the additional protection is desired. Often, this type of seal is stipulated by safety and environmental regulations. Many users of Ro-Flo compressors are in the oil and gas industry or managing biogas, therefore this type of seal is quite common.

this type of seal is stipulated by safety and environmental regulations. Many users of Ro-Flo compressors are in the oil and gas industry or managing biogas, therefore this type of seal is quite common.

If you’re uncertain which type of seal is the correct one for your application, our engineering team will be happy to discuss the advantages of each.

Get Started With Ro-Flo Compressors

If you’re ready to purchase a gas compressor, trust the experts at Ro-Flo to help you through the process. Our team has years of experience and is trusted by the top 25 largest oil and gas companies in the world. Contact us today to get started.