What are gas compressors used for?

Ro-Flo gas compressors are used for a number of different applications in the oil and gas industry, including casing gas, flare gas recovery, and tank vapor recovery. Ro-Flo compressors are also commonly used in biogas production facilities.

How many types of gas compressors are there?

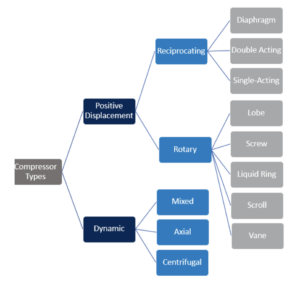

The different types of gas compressors available are shown in the diagram below. Ro-Flo compressors are Positive Displacement Rotary Vane compressors.

What is the difference between air compressors and gas compressors?

All air compressors are gas compressors, but not all gas compressors are air compressors. Air compressors are designed to only compressor air, which is a clean, consistent and stable gas. Gas compressors are designed to better handle the specific gas it is compressing. A corrosive gas stream will require a design that tolerates the corrosiveness. A flammable gas stream will require a design that reduces the risk of ignition, and so on.

Misapplying compressor designs is a common, and often costly, issue.

What is a sliding vane compressor?

A sliding vane compressor is a type of gas compressor that consists of a rotating element inside a cylindrical casing. Sliding vane compressors are used for recovering gases in industrial, biogas, and oil & gas applications.

How does a rotary vane compressor work?

A sliding vane compressor is a positive displacement compressor, meaning it decreases a specific volume of a gas, resulting in increased gas pressure. The sliding vane compressor consists of an external casing called a cylinder, the rotating element inside called the rotor, and sliding vanes. The rotor is eccentrically located in the cylinder.

The rotor has longitudinal slots that hold the vanes. As the rotor turns the vanes slide outward, due to centrifugal force, to reach the inner walls of the cylinder. The vanes will trap a pocket of gas as they pass by the compressor inlet. As the rotor continues to rotate, the volume of that pocket of gas is decreased due to the eccentricity of the rotor. The volume continues to be compressed until the leading vane reaches the discharge port, where the compressed gas is released.

If a picture is worth a thousand words, then the Compression Cycle video at this link must be worth a million.

What is a rotary vane compressor used for?

Rotary vane compressors are used for:

- Tank vapor recovery

- Flare gas recovery

- Casing gas

- Organic waste digesters

- Landfill gas

- Waste water treatment plants

- Syn gas (waste-to-energy)

- Butadiene

- Hydrogen recovery

- Condenser services

- Vacuum cooling

- Vacuum stripping

What are the basic advantages of vane compressors?

Some of the advantages of rotary sliding vane compressors include:

- Ability to handle tough gases

- Cost-efficiency

- Minimal maintenance requirements

- Easy to rebuild

- Low operation cost

- Long lifespan

- Dependability