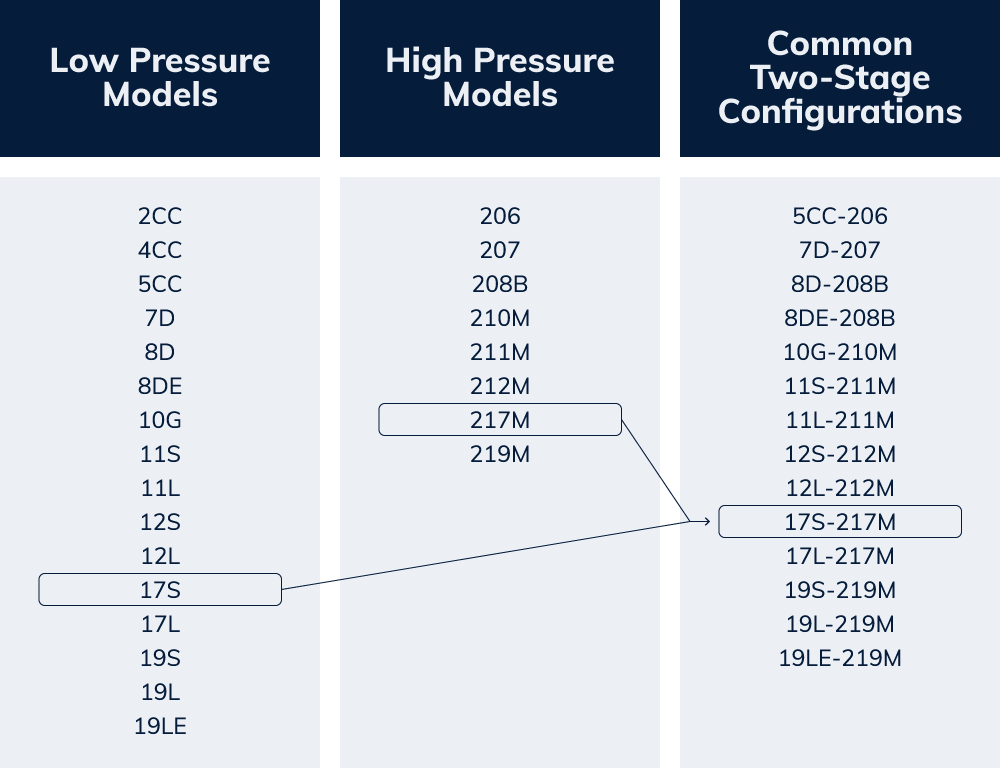

Ro-Flo’s low and high pressure models are flow-matched to enable two-stages of compression utilizing a single drive. The compressors are coupled together and then coupled to a drive, with both stages operating at the same speed.

2-Stage Systems Allow Far Greater Range

Variations on this standard setup include independent drives and Ro-Flo® models specifically selected to handle dissimilar flow requirements at different speeds. An intercooler and knockout vessel are typically required inter-stage to remove the heat of compression and any free liquids from the gas stream.

When Ro-Flo’s are configured as two stage systems for compression applications, they can produce gas discharge pressures as high as 200 psig (13.6 barg). In vacuum operation Ro-Flo’s achieve vacuum levels as low as 0.7 psia (5 kPa absolute).

Improved Reliability and Efficiency

The added cost of 2 stage systems is justified when handling sour, acidic or heavy hydrocarbon gas streams that are known to cause cost and reliability problems with other compression technologies. Further, justification of cost in vacuum service is by virtue of the higher efficiency of the equipment.