The International Trade Administration (ITA) estimates that nearly half of all food is lost before it ever reaches a consumer’s table. Much of this over $750 billion per year loss is due to problems in the cold chain—a regulated, temperature-controlled supply chain that is designed to ensure food safety and extend product life. Fortunately, vacuum cooling can help minimize losses in the food processing industry, particularly regarding agricultural products such as fruits and vegetables.

Cold Chain Requirements

The cold chain comprises every step of storage and distribution from field to table. A breakdown of the cold chain at any level can result in monumental product loss. Requirements vary according to the type, amount, and size of products. For example, frozen items such as ice cream may have required temperatures of -10F to -150F, while dairy and meat temperatures are typically 35F and 28F, respectively.

Fruits and vegetables require cool storage at approximately 55F. Vacuum cooling immediately postharvest helps to rapidly bring these products to a lower than required temperature, preventing them from deteriorating before ever reaching the next step in the cold chain.

How Does Vacuum Cooling Work?

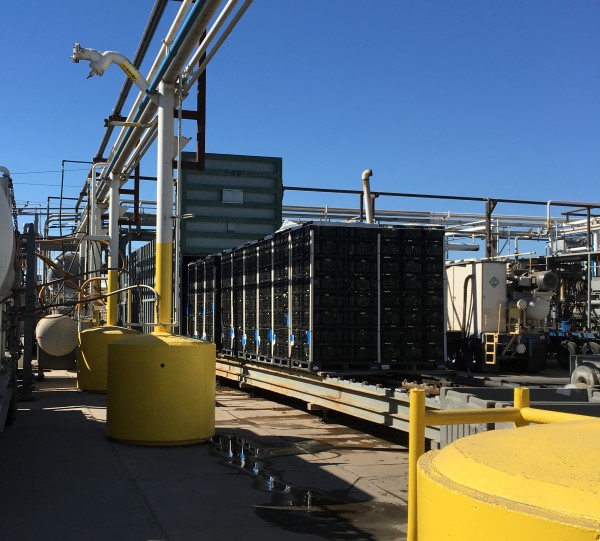

The large vacuum chamber is filled with agricultural product and then de-pressurized by removing the air in the chamber with a Ro-Flo sliding vane vacuum pump, evaporating 2 to 3 percent of the free water in the cell tissues and removing latent heat. The water vapor is condensed on a cooling coil known as a cold trap for later removal. Through refrigeration, the cold trap is maintained at or below 32F.

It takes the Ro-Flo sliding vane vacuum pump roughly 20 to 30 minutes to draw the proper vacuum on the chamber to reduce the temperature to 39F at an ambient harvest temperature of around 90F. Since the amount of water evaporated is so low, there is no danger of reducing the product weight or drying it out. When the desired product temperature is reached, the vacuum is maintained at a low level.

Benefits of Vacuum Cooling

In the summer harvest season, vegetables can deteriorate rapidly postharvest. The typical method of preservation uses a chilled cooler, which may take up to 12 hours to bring the product to the desired temperature. Under these conditions, postharvest losses of up to 25 percent are not uncommon. Because vacuum cooling takes just 30 minutes or less to reach the desired temperature, losses are far lower.

Advantages of vacuum cooling include, but are not limited to:

- No time limit for harvesting

- Product is properly cooled and ready for delivery

- Fresher, cleaner product

- Higher yield per harvest

- No ill effects on product from poor weather conditions

Product loss is a major concern throughout the food processing industry. Vacuum cooling postharvest can dramatically reduce waste in the postharvest stage of the cold chain, while improving freshness and cleanliness and allowing harvesting to continue even in poor weather.