Operation of the Sliding Vane Gas Compressor

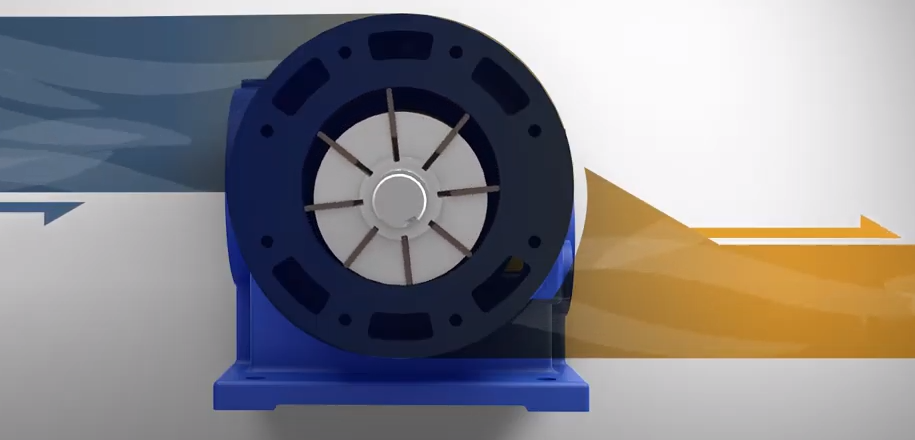

A sliding vane compressor is a positive displacement compressor, meaning it decreases a specific volume of a gas, resulting in increased gas pressure. The sliding vane compressor consists of an external casing called a cylinder, the rotating element inside called the rotor, and sliding vanes. The rotor is eccentrically located in the cylinder.

The rotor has longitudinal slots that hold the vanes. As the rotor turns the vanes slide outward, due to centrifugal force, to reach the inner walls of the cylinder. The vanes will trap a pocket of gas as they pass by the compressor inlet. As the rotor continues to rotate, the volume of that pocket of gas is decreased due to the eccentricity of the rotor.

The volume continues to be compressed until the leading vane reaches the discharge port, where the compressed gas is released. As this rotation and resulting compression is happening, small amounts of oil are being injected into the compression chamber, lubricating and protecting the compressor internals.

The Sliding Vane Compressor Has Many Benefits

Gas Compositions – sliding vanes can handle almost any gas imaginable, including acid, sour, hydrogen or heavy hydrocarbons. Other compressor technologies have limitations to specific elements of the gas stream, most commonly H2S.

A sliding vane compressor is the proper choice when compressing gas streams which are near their dew point (close to condensing to liquids).

Maintaining and Repairing

Unlike many compressor types, most regular maintenance functions on sliding vanes can be performed in the field with a few hand tools.

Casing Materials

Ro-Flo sliding vane’s standard casing materials are NACE compliant.

Operational Expense (OPEX)

Compared to some other compression technologies, the sliding vane has lower power consumption and lower routine maintenance costs

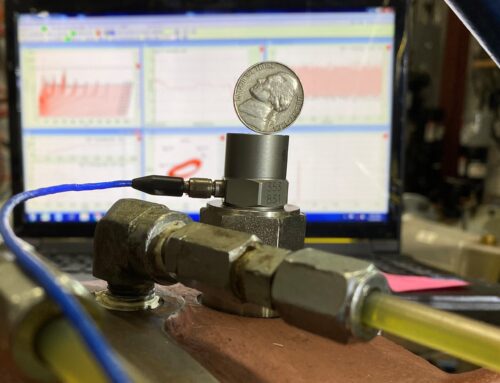

Vibration

Compared to some other compressor types, the rotary sliding vane is virtually vibration-free, requiring no special pulsation equipment or foundations.

Pressure Ratios

Rotary vane compressors can manage pressure ratios up to 7:1 in a single stage

Maximum Allowable Working Pressure – Ro-Flo sliding vane compressors can operate up to 200 psig

Lube Oil

When compared to other types of compression, sliding vane compressors consume a small amount of lube oil.

Sliding vane compressors can be found all over the world being utilized in numerous oil and gas applications, biogas management, industrial process gas, and vacuum services.

Get Started With Ro-Flo Compressors

Think you’re in need of a sliding vane compressor? Trust the experts at Ro-Flo to help you through the purchasing process. Our team has years of experience and is trusted by the top 25 largest oil and gas companies in the world. Contact us today to get started.