Why Direct Injection Compressor Lubrication Is the Best Choice

Direct injection compressor lubrication is used in sliding vane gas compressors and has distinct benefits over other types of lubrication used by other compressors. To understand why it’s necessary to understand how a sliding vane compressor works.

Sliding Vane Compressor Design and Operation

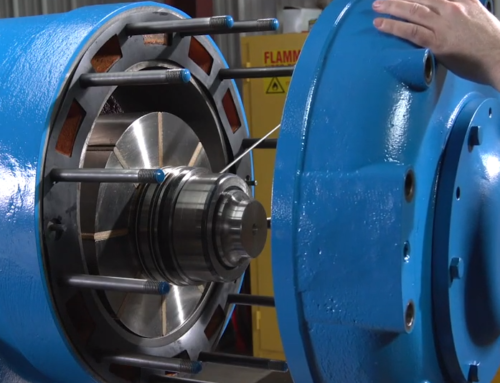

A sliding vane compressor is a positive displacement compressor, meaning it decreases a volume of a gas, resulting in increased gas pressure. The sliding vane compressor consists of an external casing called a cylinder, the rotating element inside called the rotor and sliding vanes. The rotor is eccentrically located in the cylinder. The rotor has longitudinal slots that hold the vanes. As the rotor turns the vanes slide outward, due to centrifugal force, to reach the inner walls of the cylinder. The vanes will trap a gas pocket as they pass by the compressor inlet. As the rotor continues to rotate, the volume of that pocket of gas is decreased due to the eccentricity of the rotor. The volume continues to be compressed until the leading vane reaches the discharge port, where the compressed gas is released.

Why is Lubrication Necessary?

The lubrication system serves multiple purposes in the operation of the sliding vane compressor:

- Reduce friction. The moving parts in the compressor need to be lubricated to move freely without excess friction.

- Provide cooling. The lubrication also provides a cooling effect inside the compressor to keep things from overheating due to constant movement and compressing gas.

- Carry away debris. As the compressor operates the normal wear and tear of the machinery causes deposits to form, which the lubrication system flushes out.

How Does the Lubrication System Work in a Sliding Vane Compressor?

Not all lubrication systems in compressors work the same way. The sliding vane compressor uses a once-through lubrication system, meaning that droplets of fresh oil are continuously injected onto the bearings and into the compression chamber, forming an oil film over all of the internal components. As new oil is injected, the old oil is pushed along and forced downstream of the compressors where it is typically collected in a filtered vessel.

The lubrication system consists of the following parts:

- Box: houses the complete distribution system including the drive shaft, gear set, cam, and pump.

- Pump: the heart of the lubrication system. Distributes a positive displacement of oil.

- Divider block: receives the total flow from the pump and divides it to be delivered to each lubrication point.

- Check valves: mounted at the compressor’s lubrication injection point, the check valves help maintain the distribution line’s prime.

- No flow monitoring device: to alarm or shut down when there is a lack of lubrication.

These components work together to deliver a continuous flow of lubrication through the compressor for proper operation.

What are the Benefits of Once-Through Direct Injection Lubrication?

Some significant benefits to the once-through direct injection lubrication system:

- Prevent oil contamination. Because once-through lubrication does not recirculate the oil, contamination is prevented. Compressors that recirculate the oil through the machine, become subject to harmful contaminants that can build up in oil, such as hydrogen sulfide and condensed hydrocarbons. Contaminated oil has poor lubricity and is highly corrosive to compressor parts.

- Flush out deposits. As clean oil is injected into the compressor, the dirty oil is flushed out, taking any sticky deposits that could cause the vanes or rotor to get stuck.

- Protects components from damage. Clean oil that is free of debris and deposits lubricates more effectively and thus prevents damage to the internal components of the compressor. Additionally, the clean injected oil creates a thin film of oil on all of the internal components of the compressor protecting them from corrosion.