Questions give Ro-Flo an opportunity to connect, share knowledge and experiences, and help with people’s needs.

Ro-Flo puts effort into making ‘questions’ a positive experience for the customer. Below are a few common questions to help you efficiently get the answers you need.

Rotary Vane Compressor Operational FAQ:

How does a rotary sliding vane compressor work?

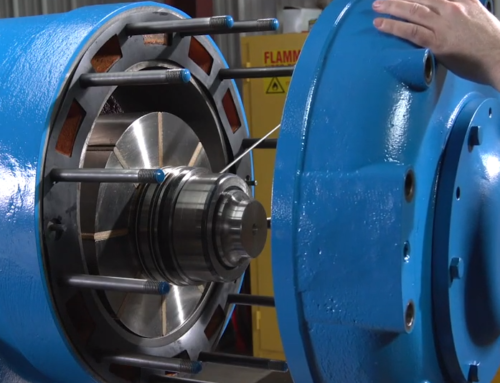

A sliding vane compressor is a positive displacement compressor, meaning it decreases a specific volume of a gas, resulting in increased gas pressure. The sliding vane compressor consists of an external casing called a cylinder, the rotating element inside called the rotor, and sliding vanes. The rotor is eccentrically located in the cylinder.

The rotor has longitudinal slots that hold the vanes. As the rotor turns the vanes slide outward, due to centrifugal force, to reach the inner walls of the cylinder. The vanes will trap a pocket of gas as they pass by the compressor inlet. As the rotor continues to rotate, the volume of that pocket of gas is decreased due to the eccentricity of the rotor. The volume continues to be compressed until the leading vane reaches the discharge port, where the compressed gas is released.

If a picture is worth a thousand words, then our Compression Cycle video must be worth a million.

What is a Ro-Flo compressor used for?

The Ro-Flo compressor has a direct oil injection feature and an overall robust design which enables it to handle the world’s worst gas streams. Here is a basic breakdown of the most common applications:

OIL & GAS

- Tank Vapor Recovery

- Flare Gas Recovery

- Casing Gas

BIOGAS

- Organic Waste Digester

- Landfill Gas

- Waste Water Treatment Plant

INDUSTRIAL PROCESS GAS

- Syn Gas (waste-to-energy)

- Butadiene

- Hydrogen Recovery

VACUUM SERVICES

- Condenser Services

- Vegetable Chilling with Vacuum Cooling

- Vacuum Stripping

Is the Ro-Flo a good air compressor?

The Ro-Flo can and is used for compressing air, however, hydrocarbon and process gas compression is Ro-Flo’s specialty. If you are looking for an air compressor for your shop, many other compressor manufacturers build plug-in-and-go systems that are better suited for that need.

Rotary Vane Compressor Performance FAQ:

How big of a compressor do I need?

Ro-Flo has developed state-of-the-art compressor selection software to accurately select the appropriate compressor for your application. Ro-Flo’s engineers will plug your application conditions into the software and provide you with the selection and expected performance curves. Or, if interested, you can register through our website and download the performance software and perform the selection yourself.

What are the system requirements for a sliding vane compressor package?

Ro-Flo provides only the bare shaft compressor. A compressor packaging company or system integrator can build the complete system to suit your needs. Generally speaking, the sliding vane system will include:

- Electrical motor or gas engine drive

- A lubrication system

- Compressor cooling system (the Ro-Flo has a water-jacketed cylinder)

- An inlet scrubber to prevent liquids from entering the compressor

- Control and monitoring instrumentation

Ro-Flo Compressors has developed a Packaging Guidelines manual to identify the system needs in much greater detail.

Rotary Vane Compressor Maintenance FAQ:

How long do the vanes (a.k.a. blades) last?

Blade life is directly related to the severity of the application. Higher pressure differentials, higher temperatures, faster-operating speeds, and contamination in the gas stream will increase blade wear. Monitoring the wear and creating a baseline to predict when the blades should be replaced will maximize the time between replacement as well as prevent failure. In a typical installation, a properly lubricated compressor can expect the blades to last at least two years.

How much oil does the Ro-Flo use?

The once-through, continuous direct injection of small amounts of lube oil into the compressor protects the internals from the contaminants of the process gas. This oil is eventually pushed downstream where it is typically collected in a separator vessel. The amount of oil needed is a factor of the compressor size, operating speed, and the composition of the gas being compressed. Ro-Flo’s state-of-the-art compressor selection software calculates the amount of lubricating oil required for the specific application and conditions. As a point of reference, a mid-size Ro-Flo operating at typical conditions in a tough vapor recovery application will require as little as 12 pints of oil per day.

Get Started With Ro-Flo Compressors

If you have more questions, do not hesitate to call the compression experts at Ro-Flo Compressors. We’d love to share our decades of knowledge and experience to ensure your success.