Anaerobic manure digesters turn animal waste into renewable energy that is used to produce electricity, natural gas and CNG to fuel trucks delivering consumer goods to market.

These digesters are also helping to protect the environment by capturing one of the most harmful gases to our atmosphere -raw methane. Manure digesters can be found on

- Dairy Farms

- Pig Farms

- Poultry Farms

- Beef Farms

Why You Need a Manure Digester

Manure and other animal waste materials are collected in a digester lagoon, pit, tank or other structure. As the bacteria breaks down the organic matter, gases are produced. The digester will have some sort of roof to capture the gases coming off this process. This gas is then collected, most likely by a compressor. These gases usually contain about 60% Methane and 40% Carbon Dioxide. They can also be heavily H2O saturated. These gas streams also have the potential of carrying high levels of Hydrogen Sulfide, a very dangerous and corrosive gas. There are many benefits that come from digesters, both economically and environmentally.

- Lower electrical, natural gas, and heating costs

- Income from selling excess energy back to the grid

- Enhanced fertilizer value of the digested manure

- Fewer pathogens in manure (e.g., fecal coliform bacteria)

- Less odor than raw manure

- More stable nitrogen readily available to crops

- Reduced greenhouse gas emissions

Biogas Upgrading:

When biogas is used for heating or producing electricity, only the hydrogen sulfide and water need to be removed. Gas that will be used to fuel vehicles or sold into the pipeline will need to be cleaned or purified to meet US pipeline specifications. One of the most common methods of removing these impurities is water scrubbing. This process can remove both CO2 and H2S simultaneously by taking advantage of their higher water solubility compared to methane. Compression is used to enhance absorption. After absorption, the purified biogas, which is more than 97% pure methane, is collected from the top of the scrubber. The remaining liquid effluent, containing high concentrations of CO2 and small amounts of methane, is treated in a flash tank to recover the remaining methane. This purified methane gas can then be sold into the pipeline, thus generating revenue back to the farm.

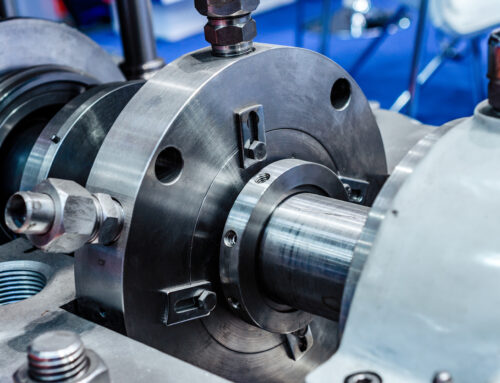

Why Use a Ro-Flo Rotary Vane Compressor

The Ro-Flo rotary vane compressor is a great choice for this application, due to it’s the ability to handle heavily saturated gas streams. By design, the oil lubrication system injects small amounts of oil directly into the compressor at multiple points, lubricating and protecting the seals, bearing, blades, rotor and cylinder wall from the wet and corrosive gas.