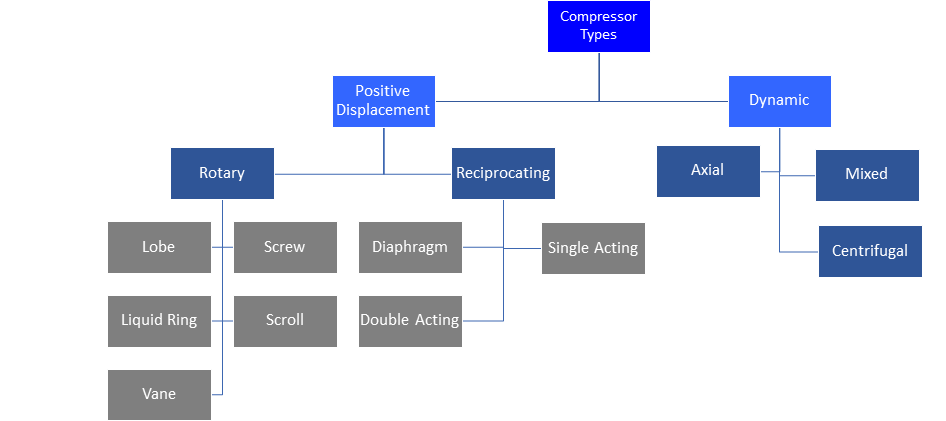

A compressor is a mechanical device that increases the pressure of a gas by reducing its volume or by imparting velocity on the gas. This can be done in numerous different types of gas compressors.

Positive Displacement Compressors

Positive displacement compressors are machines in which successive volumes of gas are confined within a closed space; the volume of the confined space is then decreased, thus increasing the pressure.

Dynamic Compressors

Dynamic-type compressors are machines in which gas is compressed by the mechanical action of rotating vanes or impellers imparting velocity to the gas.

Types of Positive Displacement Compressors

There are two types of positive displacement compressors:

Reciprocating Compressors

The compressing element in this type of compressor is a piston that has a reciprocating motion inside a cylinder. Compressor capacity and horsepower are affected by piston displacement and cylinder clearance. The flow capacity of a given cylinder is a function of piston displacement and volumetric efficiency. Volumetric efficiency is a function of cylinder clearance, compression ratio and the properties of the gas being compressed

Rotary Compressors

Compression is affected by the positive displacement action of rotating elements. There are several types of rotary compressors, two very popular types are:

- Rotary screw compressors use two rotating helical screws to compress the gas. Compression takes place between the rotors and the discharge end of the compression chamber.

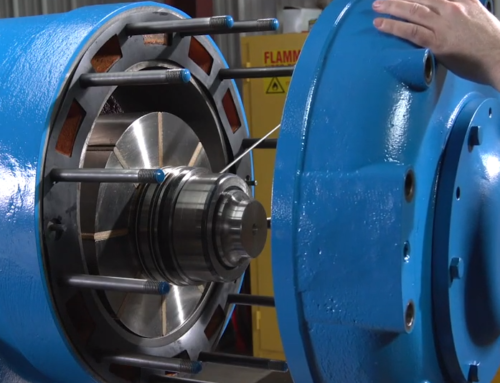

- Rotary sliding vane compressors consists of an external casing called a cylinder, the rotating element inside called the rotor, and sliding vanes. The rotor is eccentrically located in the cylinder. The rotor has longitudinal slots that hold the vanes. As the rotor turns the vanes slide outward, due to centrifugal force, to reach the inner walls of the cylinder. The vanes will trap a pocket of gas as they pass by the compressor inlet. As the rotor continues to rotate, the volume of that pocket of gas is decreased due to the eccentricity of the rotor. The volume continues to be compressed until the leading vane reaches the discharge port, where the compressed gas is released

Types of Dynamic Compressors

There are two types of dynamic compressors:

- Axial Compressors. A rotating, airfoil-based compressor in which the gas, typically air, flows parallel to the axis of rotation. An axial compressor consists of a series of stages where each stage comprises a rotor and a stator. The kinetic energy of the air is increased by the rotor and then diffused (the air velocity is reduced) in the stage to increase the static pressure at the outlet of the stage. Axial compressors are basically high-flow, low-pressure machines, in contrast to the lower flow, high-pressure centrifugal compressors. Axial compressors are more efficient than centrifugal compressors. However, centrifugals are less vulnerable and, hence, more reliable, have wider operating ranges, and are less susceptible to fouling.

- Centrifugal Compressors. A centrifugal compressor imparts kinetic energy into the gas stream by increasing the velocity of the air using a rotating element called an impeller and then converts this kinetic energy into potential energy in the form of pressure. The gas enters the impeller at the center and the rotating fins, or vanes, increase the velocity of the gas as it moves radially outward to the outer diameter of the impeller. Due to the continuous flow through multiple stages, centrifugal compressors are designed to thrive in higher capacities and are best suited for applications above 200 total horsepower.

Get Started With Ro-Flo Compressors

If you’re ready to purchase a gas compressor, trust the experts at Ro-Flo to help you through the process. Our team has years of experience and is trusted by the top 25 largest oil and gas companies in the world. Contact us today to get started.