What Advantages Are There to Using a Rotary Sliding Vane Gas Compressor?

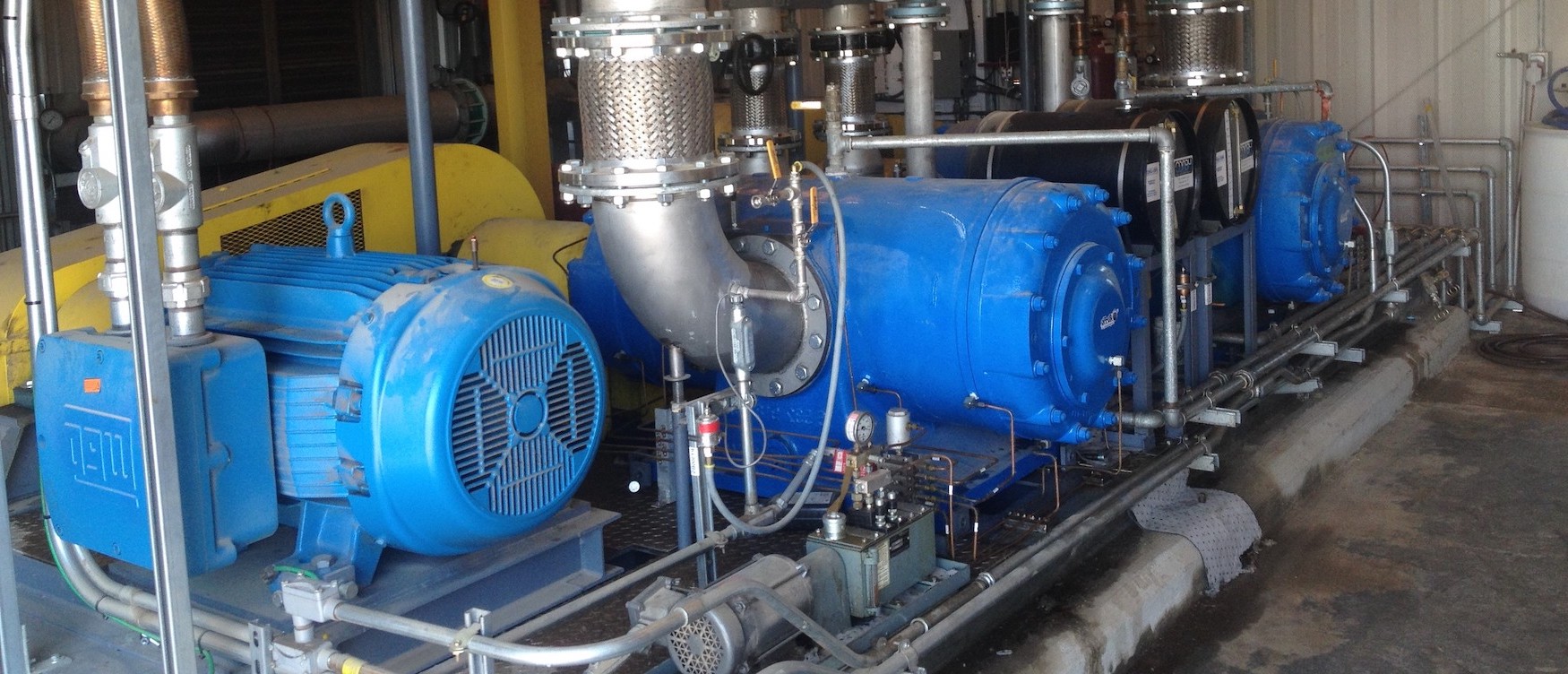

The rotary sliding vane gas compressor is a cleverly designed, yet simple machine. It consists of a rotating element (the rotor) inside of a cylindrical casing (the cylinder ). The rotor contains vanes that slide out as the rotor turns making contact with the inner wall of the cylinder. The rotor is offset, therefore as it rotates the pocket of trapped gas between the vanes and the cylinder wall is decreased, compressing the gas.

Rotary vane compressors are used in a wide variety of applications because of the many advantages they offer, such as:

- Can Handle Tough Gases. The robust design of rotary vane compressors makes them capable of handling sour, acidic, and wet gases. The once-through lubrication system continuously and consistently coats the compressor internals to protect them from the tough gases.

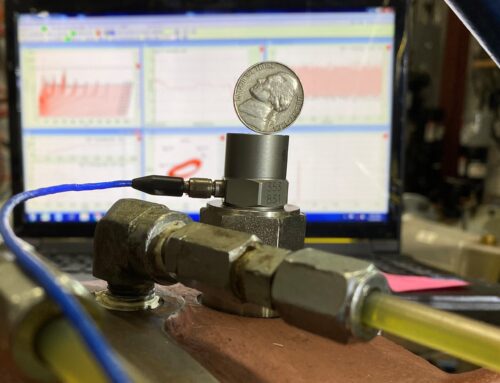

- Low Maintenance. Rotary vane compressors require very little maintenance. If liquids are kept from entering the compressor, and the compressor is properly lubricated, the user can expect years of operation.

- Easy to Rebuild. Another advantage to the simple design of the rotary vane compressor is that it is easy to take apart and rebuild. A full rebuild of a Ro-Flo sliding vane compressor can usually be done in a single shift. When problems arise or maintenance is necessary, downtime is minimized. Productivity resumes quickly and very little time or funds are lost.

- Low Operation Cost. On the subject of funds, another advantage to rotary vane compressors is that they operate at a relatively low cost in comparison with other types of industrial machinery. Efficient operation and maximized up time results in low operating costs.

- Long Life Span. With proper lubrication and routine maintenance, the sliding vane compressor can operate efficiently for decades.

Ready to Learn More about how Rotary Vane Compressors can solve your tough compression application?