Fundamentals of Active Compressor Cooling:

One misunderstood aspect of a Ro-Flo rotary vane compressor is the integral cooling system. When looking at the compression system as a whole, the compressor cooling system temperature is sometimes adjusted to help control the process gas temperature. Adjusting the coolant temperature will affect the gas temperature, but that’s not the intent of the design. The actual design is to control internal clearances for efficiency and protection due to thermal growth differences between the steel rotor and the Ductile iron cylinder & cylinder heads. The recommended coolant discharge temperature is 100°F to 110°F (37°C to 44°C). It’s not always possible to maintain this range, so these are not pass/fail limitations. Going beyond this range results in the following:

- In hot ambient conditions it’s common to see 140°F to 150°F (60°C to 66°C) coolant discharge temperatures. This doesn’t damage the compressor, but it does result in increased internal clearances which negatively affects efficiency.

- There’s no definitive pass/fail point, but avoid exceeding 180°F (83°C), as temperatures above this can start damaging the cylinder head gaskets.

- There’s also no definitive pass/fail point at the cold end, but you should avoid going lower than 100°F (37°C) because internal clearances get smaller until rotor to cylinder head contact occurs.

Types of Compressor Cooling Systems:

There are three common types of cooling systems, none of which is inherently better than the others, as long as they operate within the aforementioned temperature ranges:

Open Loop Cooling System

The coolant is typically water from a source such as municipal water systems. The coolant does not become contaminated so it can be poured down the drain or sent to other disposal methods. The temperature is typically controlled by a temperature control valve on the inlet side with the thermostat on the discharge side. The thermostat should be as close as possible to the compressor so it reacts quickly to changing temperatures.

Closed Loop Cooling System

This is the most common and is composed of a radiator, coolant pump & thermostatic diverting or mixing valve. When the coolant is below the valve’s set temperature, it will divert or mix the coolant in a short loop until the temperature reaches a point the thermostat changes the valve position to circulate the coolant to the radiator. One benefit of this system is that an automotive type radiator fluid can be used helping prevent corrosion in the compressor water jackets.

Plant Systems

Many locations now have common, plant-wide coolant systems that can be tapped into for any equipment that needs it. If it doesn’t operate within the recommended temperature range, a temperature control valve can still be used.

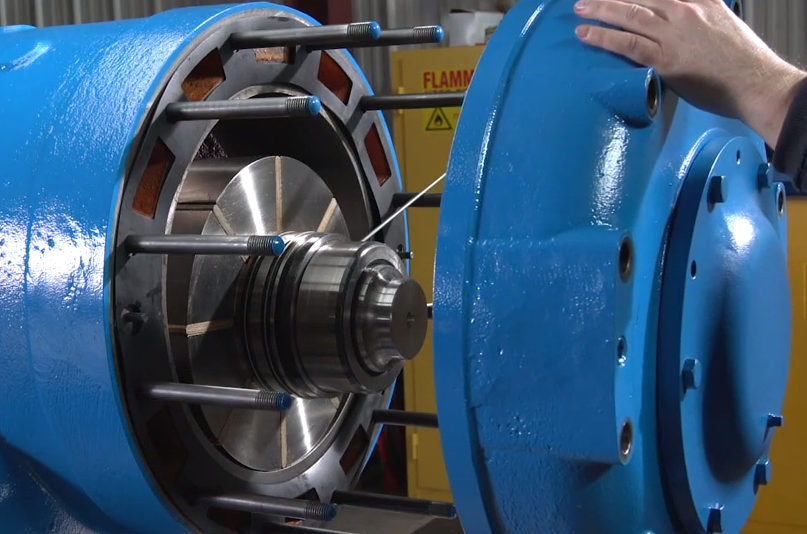

Integral Cooling System Design

The cylinder and cylinder heads on Ro-Flos are made from cast Ductile iron. The water jackets for the coolant are cast into them making them integral. They also share the coolant by way of matched “ports” cast into the ends of the cylinder and inboard face of the cylinder heads. Cylinder head gaskets seal the ports to prevent coolant leaks. IMPORTANT: The coolant side has an MAWP of 50 PSIG.

Every cylinder has an NPT plug (size determined by the compressor model), on the top, and two (one on each side), near the bottom. For efficiency, the coolant should flow into one of the lower fittings (either one), and discharge at the top.

The unused lower plug can be used for equipment such as valves with a hose fitting making draining the coolant much easier for maintenance. Note: The coolant must be drained before loosening the cylinder head studs to prevent coolant from flooding the compressor. Isolation valves on each side of the compressor allow you to drain only the compressor, and not the entire system.

Reduced coolant velocity through the compressor often results in debris fallout. This should be cleaned during normal maintenance to prevent hot spots in the water jackets. This is usually accomplished by flushing with a hose or power washer.

Important Operational Aspects

One of the most important operational aspects of the cooling system is that it shuts down when the compressor is shut down. If the compressor has full heat soak and is shut down for a short period of time with the coolant system running, the cylinder will quickly cool while the rotor remains close to operating temperature. This produces the worst-case scenario that can result in a complete loss of internal clearances resulting in rotor to cylinder head contact damage.

In cold climates, compressors should be protected from coolant freezing in the water-jackets. Draining coolant is the safest, but automotive coolant offers protection to its design limits. Freezing can crack the cylinder and/or cylinder heads.

The inlet plenums have little to no water jacket exposure, so the integral cooling system will not cool incoming process gas causing liquids to condense out in the plenum.

Get Started With Ro-Flo Compressors

Do you have any compressor cooling questions? At Ro-Flo Compressors, we are THE rotary vane compression experts. Please contact us today or give us a call to discuss your needs.