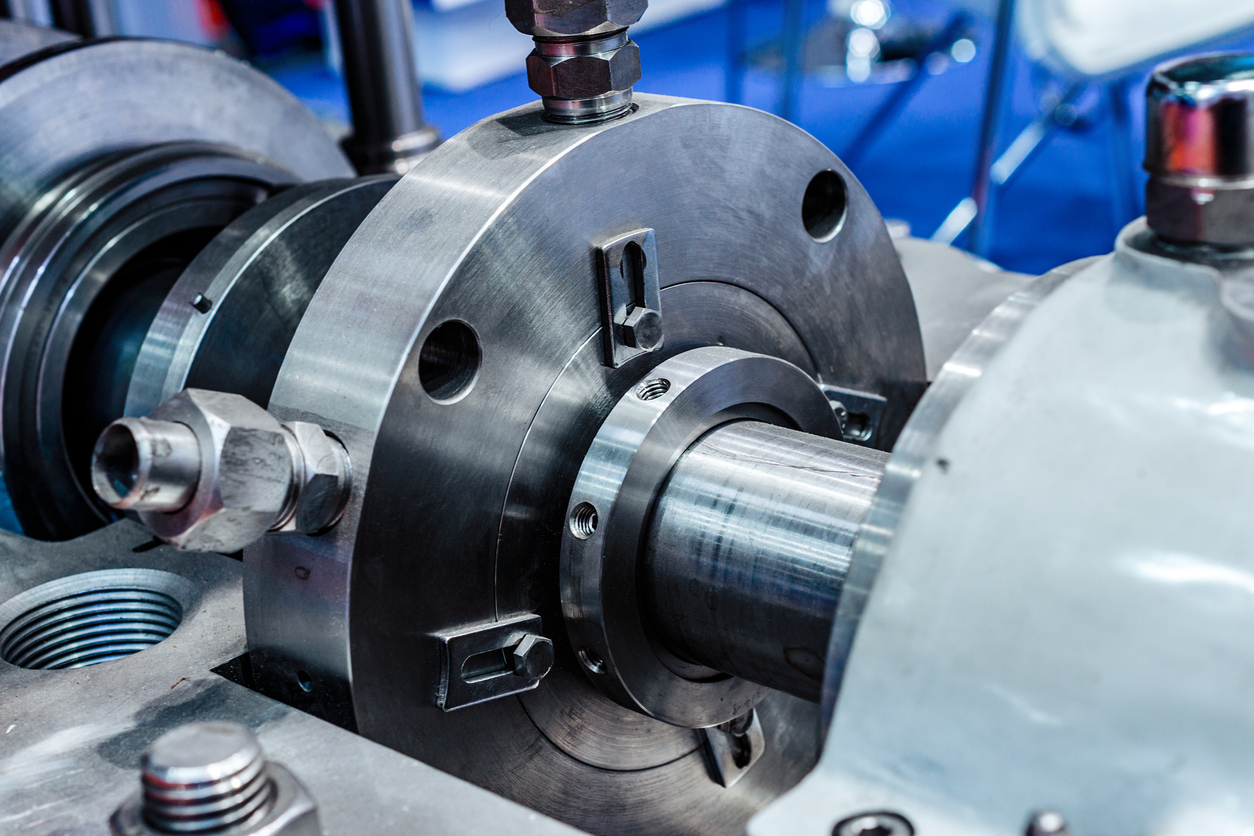

An essential aspect of the design of a gas compressor is the mechanical seal. A mechanical seal minimizes or eliminates gas leakage at the interface between a rotating shaft and the stationary housing.

Tip #1: Choose the Correct Materials

Choose the correct construction materials for the application. The materials selected must endure the temperature extremes, pressure differentials and be tolerant of the corrosive process gases of the specific gas compressor application. Additionally, the compressor sealing face materials must have proper resistance to friction, frictional heat, and resistance to wear. One of the various grades of mechanical carbon is often chosen for the sealing faces

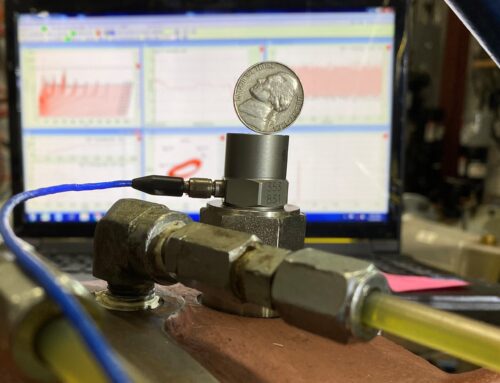

Tip #2: Consider the Form of Lubrication

All friction mechanical seals require some form of lubrication to cool and help seal the gases in the gas compressor. Pre-lubing the seal faces and cavities will best protect the components during start up and the first moments of operation. Waiting for the lube system to get lubricant to all areas of the seal after start up can have a detrimental effect on the seal’s longevity.

Tip #3: Check the Spring System

The compressor sealing faces of a mechanical seal are pushed together by some form of spring system. Before assembling the seal onto the shaft, confirm that the spring system is freely working and not hung up by pressing gently against the primary ring assembly, taking caution to avoid direct contact with the sealing surface with your hand.

Tip #4: Check Your Installation: See Mechanical Seal Diagram

This tip is specific to Ro-Flo’s Single Face Mechanical Seal. Specifically, installing the seal onto the sliding vane compressor. Refer to the mechanical seal diagram below for the specific component names. The first step of the installation is sliding the mating ring into place. Due to the o-ring on the inside diameter of the mating ring, this is a snug fit, and some effort is required to slide it onto the shaft.

The sealing face of the mating ring is highly polished, providing the best sealing surface. It is vital that this face, where the carbon primary ring contacts it, does not get scratched, dinged, or left pitted due to corrosion from salty fingerprints. And here’s the tip: use the Locking Sleeve to push the mating ring down the shaft. This will keep the mating ring square to the shaft, preventing it from getting cocked and stuck, and keep your hands off the sealing face.

Get Started With Ro-Flo Compressors

If you have more questions, do not hesitate to call the compression experts at Ro-Flo Compressors. We’d love to share our decades of knowledge and experience to ensure your success. Contact us today to get started.