What Is a Two Stage Gas Compressor?

When the discharge pressure needed for an application cannot be reached with a single stage gas compressor, a two stage gas compressor is needed. While a two stage gas compressor is more expensive, more complicated to operate, and requires additional equipment, there’s simply no other way to reach a higher discharge pressure if a single stage gas compressor isn’t cutting it. Two stage gas compressor systems are also a solid choice for handling sour, acidic, or heavy hydrocarbon gas streams that cause problems for other types of systems.

Here’s what you need to know about two stage compressors.

How Two Stage Gas Compressors Are Made

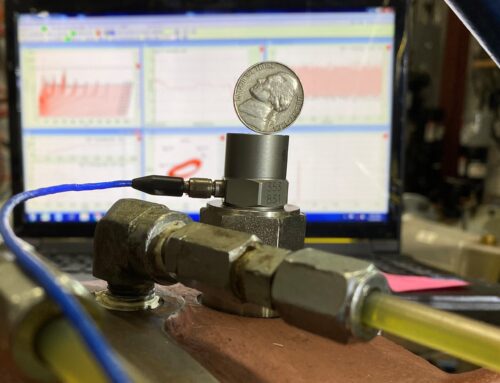

Ro-Flo two stage gas compressors combine a high pressure model and a low pressure model on one drive to create an optimal solution when high discharge pressure is needed. A Ro-Flo low pressure gas compressor is coupled with a high pressure model; they are flow-matched to enable two stages of compression with a single drive. Both stages operate at the same speed.

While this is the standard setup, there are variations. One includes independent drives and Ro-Flo models specifically chosen to handle dissimilar flow requirements at different speeds. An intercooler and knockout vessel are often required inter-stage to remove the heat of compression and free liquids from the gas system.

What Two Stage Gas Compressors Do

Two stage gas compressor systems allow for a far greater range, along with improved reliability and efficiency. A gas compressor system made with two Ro-Flo compressors can produce gas discharge pressures as high as 200 psi (13.6 barg). In a vacuum operation, Ro-Flo two stage gas compressor systems can achieve vacuum levels as low as 0.7 psia (5 kPa absolute).

How to Choose a Gas Compressor for Your Application

When you work with Ro-Flo, our team makes choosing a gas compressor easy. We’ll help you decide upon a system that meets your needs by factoring in the following information:

- The application the compressor system is being used for

- The type of gas being handled

- The pressures needed

- The compression ratio (the higher the ratio, the more likely a two stage gas compressor is needed)

- The site where the system will be used

- The suction and discharge temperatures

- The capacity needed

Knowing these variables, we can determine whether a two stage gas compressor is needed and come up with the exact specifications needed for your system. At some compression ratios, single stage and two stage gas compressors may both be options. To decide between the two, it’s important to factor in that a two stage gas compressor system is much more complex, and may require additional training for operators and be more difficult to maintain and repair. The initial cost, too, is higher. A two stage compressor does offer a lower discharge temperature and if both single stage and two stage gas compressors are an option, the two stage compressor will operate more efficiently.