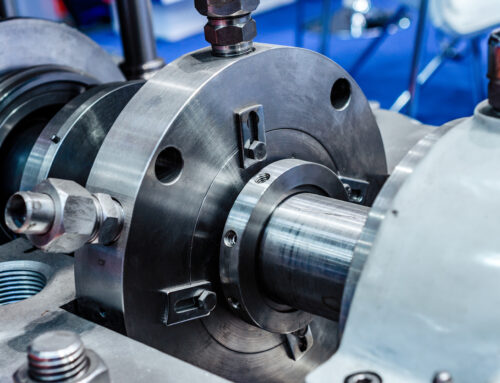

A vapor recovery compressor is a specially designed compressor used for handling wet, heavy , or acidic gases. Its main purpose is to recover vapor that would otherwise be released into the air, mitigating air pollution. The captured vapor is then cleaned, separating the liquids from the gases. Rotary sliding vane compressors are the best type of compressor for this application, as they can easily handle these tough and varying gases and have the ability to run 24 hours a day, seven days a week, requiring very little maintenance.

How A Vapor Recovery Compressor Is Used

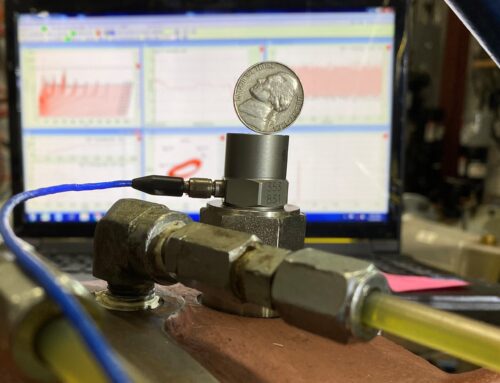

Ro-Flo vapor recovery compressors are commonly used in oil storage tank applications. According to the US EPA, there are about 500,000 oil storage tanks in the United States. These tanks hold the crude oil for a brief amount of time, until it is piped or trucked away for processing. While sitting in the tanks, the crude oil releases hydrocarbon gases (vapors) that were contained in the oil. These vapors fill the space in the tank above the liquid. Rather than venting or flaring these gases, the vapor recovery compressor collects the gases. The gases are first sent through a separator to knock-out and collect any remaining liquids. These liquids are typically piped back into the storage tank. The vapors are sent down the pipeline for sale or used as an onsite fuel supply.

Benefits of Using a Vapor Recovery Compressor (VRU)

VRU compressors are used to reduce emissions, helping the environment and reducing the carbon footprint of the production company. But they also save the production company money by utilizing the gas onsite and generating revenue by selling the high BTU gases. Venting or flaring this valuable product is wasting this opportunity. The EPA has published a study showing that an average four tank VRU system can save over $500,000 in fuel costs annually and have a return on investment in just a few months.

Why Choose a Ro-Flo Vapor Recovery Compressor

Rotary screw and reciprocating compressors can be used for vapor recovery, but rotary sliding vane compressors are the best solutions. Their ability to handle varying gas compositions and varying gas flows is unmatched by the others. Sliding vane compressors only require a small amount of oil for lubrication and protection of the compressor internals; they require little maintenance and much of the maintenance and repair work can be done onsite in a short amount of time using just three tools.

There is no better choice than a time-tested rotary sliding vane compressor from Ro-Flo. Contact our team today to get started.