It’s a hot muggy summer day and you’re enjoying an ice-cold glass of lemonade when you notice that the outside of the glass is wet.

Why is the outside of the glass wet?

The air near the outside of the glass has been cooled below its dew point temperature and water from the air has condensed onto the glass.

Dew Point Definition

The dew point is the temperature (at a given pressure) at which a fluid will change state from a vapor to liquid. If you are above the dew point temperature, the fluid will remain in a vapor state. If you are below the dew point temperature, the fluid will begin to condense.

Dew Point and Air

The composition of Earth’s air always contains some water and when you cannot see this water, it is in a vapor (or gas) form. Although air is a mixture of a number of fluids such as Nitrogen and Oxygen, as air is cooled, water will be the first fluid from the air to start condensing from a vapor to a liquid because it has the highest dew point temperature. If you were to continue to cool the air to very low temperatures, the other fluids would also condense from a vapor to a liquid.

You may have gathered from watching weather reports that the dew point temperature is not always the same from one day to another. This is because the dew point temperature changes depending upon the barometric pressure (the air’s pressure) and the amount of water within the air (the air’s composition or humidity).

- If you increase the air pressure by going to a lower elevation, the dew point temperature also increases.

- If you add moisture to the air (more water vapor within the air) you also increase the dew point temperature

If it’s muggy out, as described above, there is more water vapor in the air; hence, the air dew point temperature will be higher and it will be easier for water to condense on your ice-cold glass of lemonade because the air temperature doesn’t need to drop much to get below the dew point.

Dew Point and Process Gases

Similar to air, process gases and process gas mixtures have dew point temperatures where gas turns into a liquid.

- If you increase the pressure of a process gas, you increase the dew point temperature of the process gas.

- If you change the composition of a process gas, you change the dew point temperature.

For example, if you have a gas grill, chances are your grill includes an LP tank that supplies the gas. LP stands for liquid propane, thus the propane in the tank is a liquid, yet when you turn the grill on, its gas that’s being burned in the burners.

The propane in the tank is at a higher pressure. A full 20 pound tank on a 70°F day has an internal pressure around 145 psig. The dew point temperature of propane at 145 psig is 87.5°F. Since the ambient temperature of 70°F is below the dewpoint temperature of 87.5°F, the propane in the tank is in a liquid state.

When you open the tank valve and allow propane into the grill burners, the propane pressure at the burners drops close to 0 psig and the dew point temperature drops to -44°F. Since the ambient temperature of 70°F is above the dew point temperature, the propane is in a vapor (gas) state.

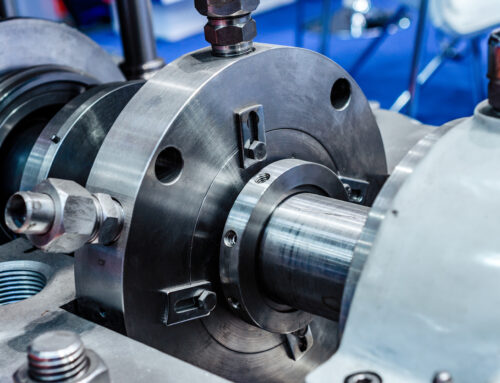

Dew Point and Compressors

There is a saying: “Ro-Flo Compressors makes great compressors, but terrible pumps*.”

To explain: Compressors compress gas and transport gas vs.Pumps increase the pressure of a liquid and transport liquid

Like most compressors, Ro-Flo’s are designed for gas and if excessive amounts of liquid are sent through a compressor, it is likely to damage the compressor.

Ro-Flo’s commonly handle gas mixtures that:

- are near dew points

- contain fluids with higher dew point temperatures or dew points near ambient temperatures

As a result, the probability of liquids being present in the process gas stream is very high for Ro-Flo Compressors. It is extremely important to know your process gas and understand where its dew point temperatures are.

* Not to be confused with “vacuum pumps”. Vacuum pumps remove gas to create vacuum. Ro-Flo Compressors make excellent vacuum pumps as well.

Dew Point and Compressor Systems

When designing a compressor system, the process gas dew point temperatures need to be determined at the pressures that are expected in your compressor system. Not only should you consider your design, off-design and future process operating conditions, but you should also look at the conditions when the equipment has been shut down. The main locations to evaluate the process gas include:

- Compressor suction

- Compressor discharge

- Downstream of any heat exchangers

If the process gas at any location is near the dew point, the compressor system design should include components to remove and manage any condensed liquid within the process. Items to consider are:

- Separator/Scrubber/Knock-Out Vessels

- Should be located near the compressor suction

- On 2-stage compressor systems, there should be a vessel for each compressor

- Vessels should include automatic drain valves and/or pumps as required

- Low point drains for piping

- Heat exchanger design

- Inlet to heat exchanger should be located at the top of the heat exchanger

- Discharge from heat exchanger should be located near the bottom of the heat exchanger

- The piping should be sloped/pitched away from the compressor

- Consideration should be given to long piping runs that may lose or gain heat from the ambient surroundings.

- Drain valves/pumps

Learn More With Ro-Flo Compressors

All of the above are also discussed in detail in Ro-Flo’s Installation, Operation and Maintenance Manual as well as Ro-Flo’s Packaging Guidelines. Both of these manuals can be found on Ro-Flo’s website:

Additionally, don’t hesitate to contact Ro-Flo Compressor’s engineering team to access years of experience with rotary vane compressors.