Pneumatic Conveying

Using compressed gas (air) and/or vacuum to move bulk materials like granules and powders is referred to as pneumatic conveying. In industries such as cement, mining, chemicals, and plastics, pneumatic conveying systems are crucial, often acting as the lifeblood of the production facility. For over 40 years, Ro-Flo Compressors and Vacuum Pumps have been at the heart of these systems, trusted by producers for their reliability and efficiency. […]

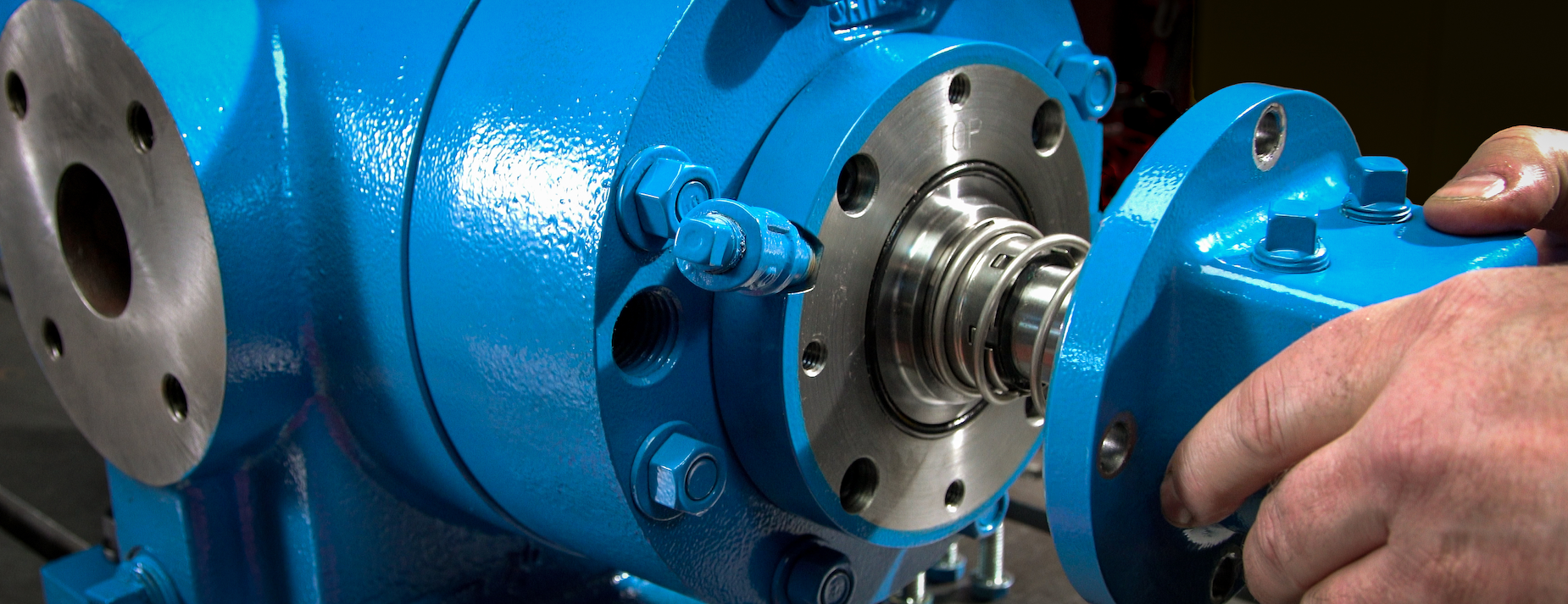

Tips for Installing Your Mechanical Seals

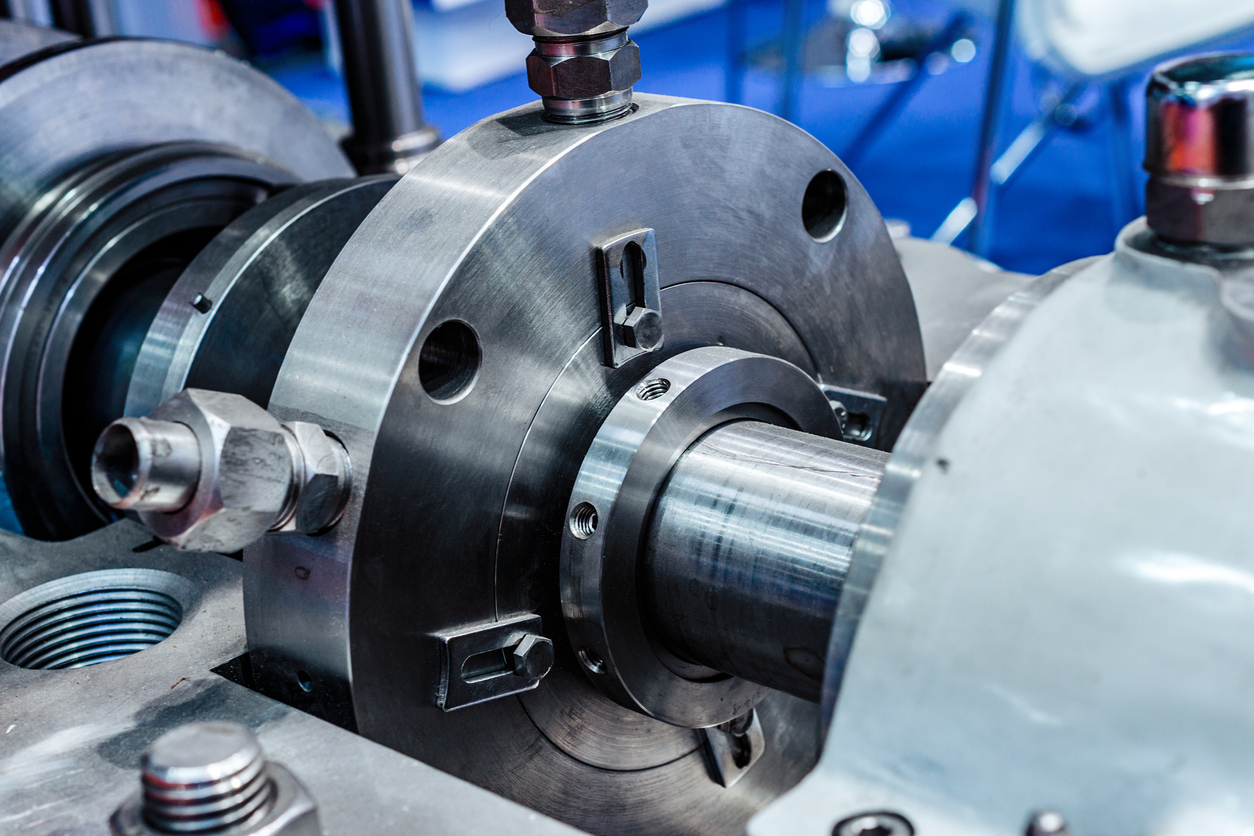

An essential aspect of the design of a gas compressor is the mechanical seal. A mechanical seal minimizes or eliminates gas leakage at the interface between a rotating shaft and the stationary housing. […]

Sources of Renewable Natural Gas (RNG)

There is certainly a lot of talk about renewable natural gas and the important role it currently plays in the U.S. energy sector and even more discussion about its use in the coming decades. Let’s take a closer look at the most common renewable natural gas sources and the positive effect it has on decreasing emissions. […]

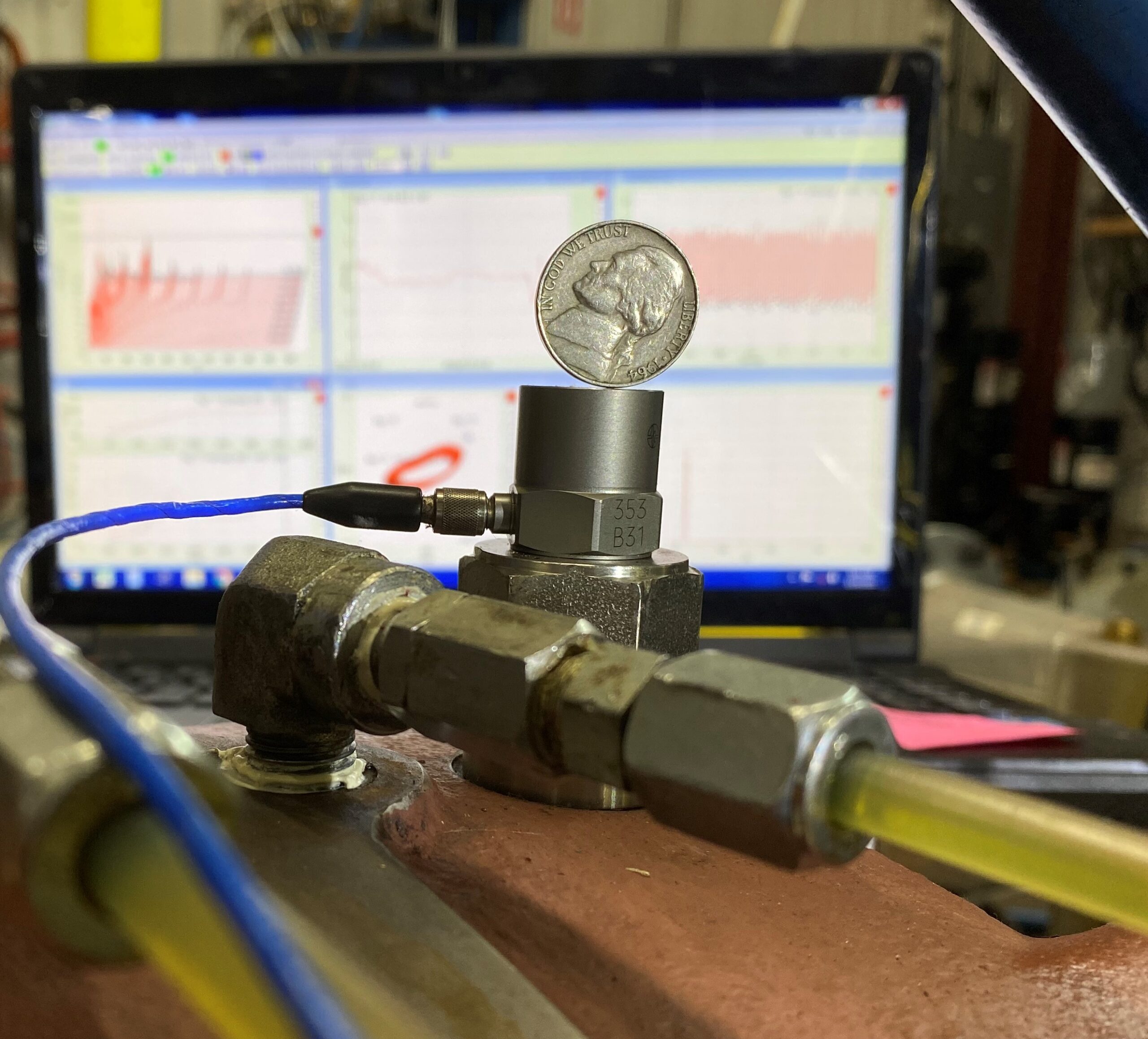

Understanding Compressor Vibration

Vibration is inherent to compressors and different types of compressors each have their unique vibration signatures. […]

Rotary Vane Compressor FAQs

Questions give Ro-Flo an opportunity to connect, share knowledge and experiences, and help with people’s needs. […]

Collecting Methane With a Manure Digester

Anaerobic manure digesters turn animal waste into renewable energy that is used to produce electricity, natural gas and CNG to fuel trucks delivering consumer goods to market. […]

What is Dew Point?

It’s a hot muggy summer day and you’re enjoying an ice-cold glass of lemonade when you notice that the outside of the glass is wet. […]

Designing Reliability Into a Gas Compressor

Gas Compressors have to be designed to handle large changes in pressure and temperature in a large variety of gas mixtures.

Gas Compressor Capacity Control

Gas compressors used in various industries, from oil and gas tank vapor control to biogas methane capture, require capacity control to handle the variability in gas production. This article will provide a brief overview on methods of controlling positive displacement compressor capacity. […]

Compressor Cooling – Understanding Ro-Flo’s Integral Cooling System

One misunderstood aspect of a Ro-Flo rotary vane compressor is the integral cooling system. When looking at the compression system as a whole, the cooling system temperature is sometimes adjusted to help control the process gas temperature.

Troubleshooting Your Rotary Vane Compressor

When you choose a Ro-Flo compressor, you’re choosing a compressor design that stands the test of time.

What is the Difference between Single and Double Face Mechanical Seals?

If you’re thinking about purchasing a high pressure gas compressor from Ro-Flo for your application, you’ve likely noticed that we offer two options for the shaft seals.

Benefits Of Using A Vapor Recovery Compressor

A vapor recovery compressor is a specially designed compressor used for handling wet, heavy , or acidic gases.

Rotary Vane Compressor Health and Longevity

Rotary vane compressors are known for their ability to handle saturated and corrosive gases. Their durability in tough environments is why they are commonly chosen for vapor recovery, flare gas and various industrial process gas applications.

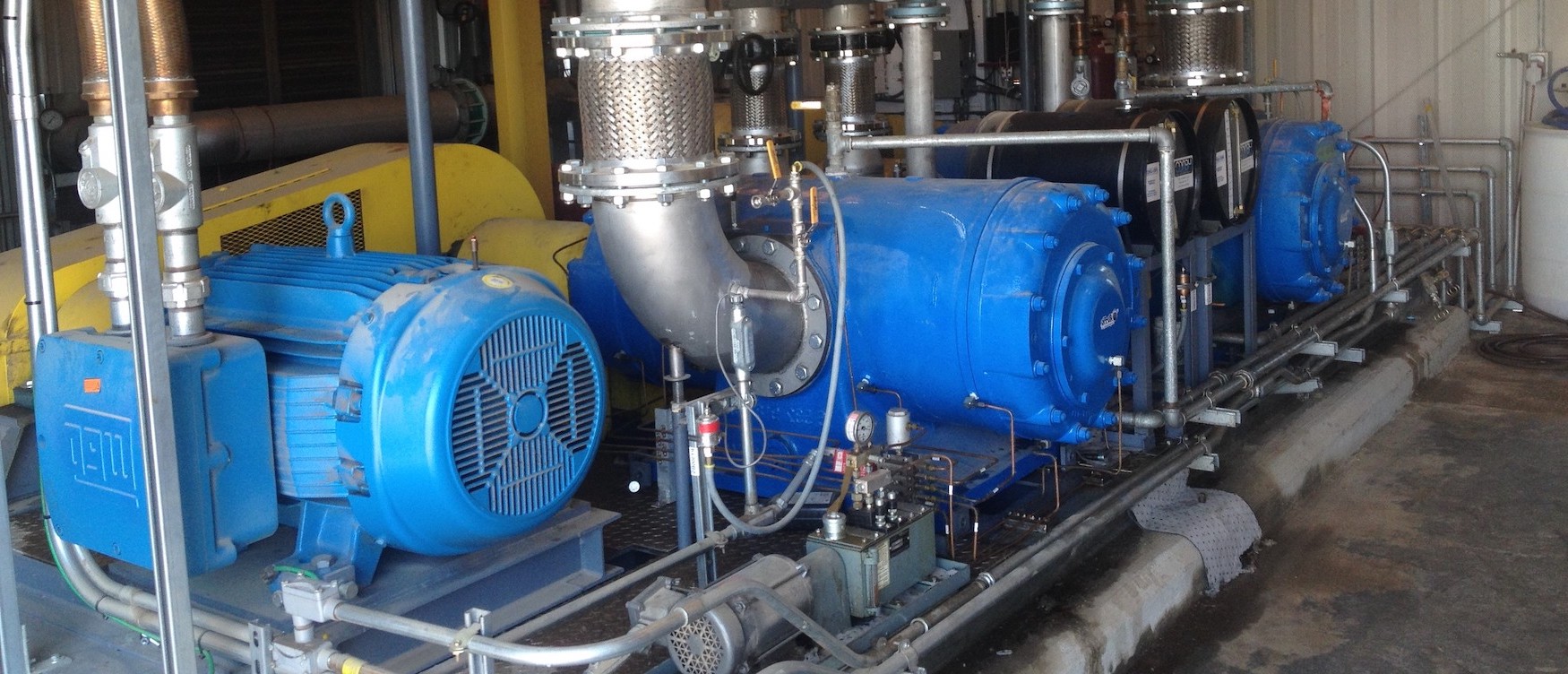

What are the Advantages of a Two Stage Gas Compressor?

When the discharge pressure needed for an application cannot be reached with a single stage gas compressor, a two stage gas compressor is needed. While a two stage gas compressor is more expensive, more complicated to operate, and requires additional equipment, there’s simply no other way to reach a higher discharge pressure if a single stage gas compressor isn’t cutting it.

Biogas Compressor Maintenance Schedule

RoFlo Compressors reviews the best biogas compressor maintenance schedule to help keep them in perfect condition and working order.

Rotary Vane vs. Reciprocating Compressors – Compressor Comparison

RoFlo Compressors reviews the compressor comparison between the rotary vane and reciprocating compressors.

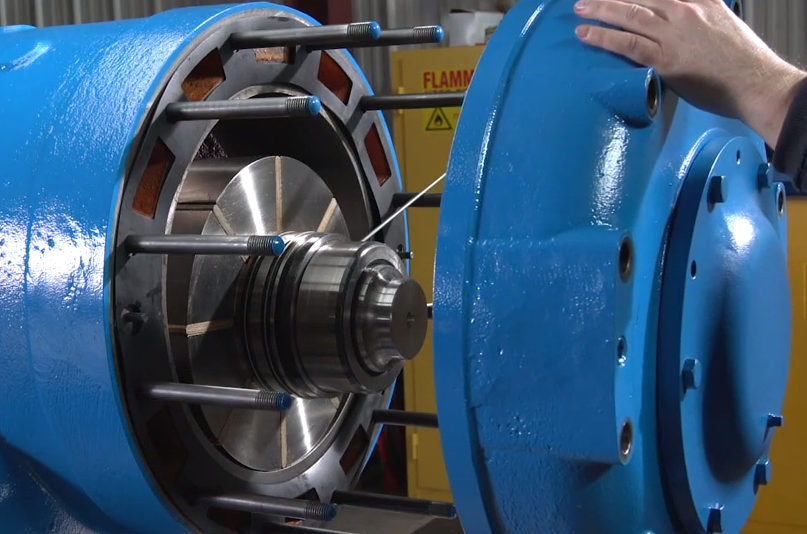

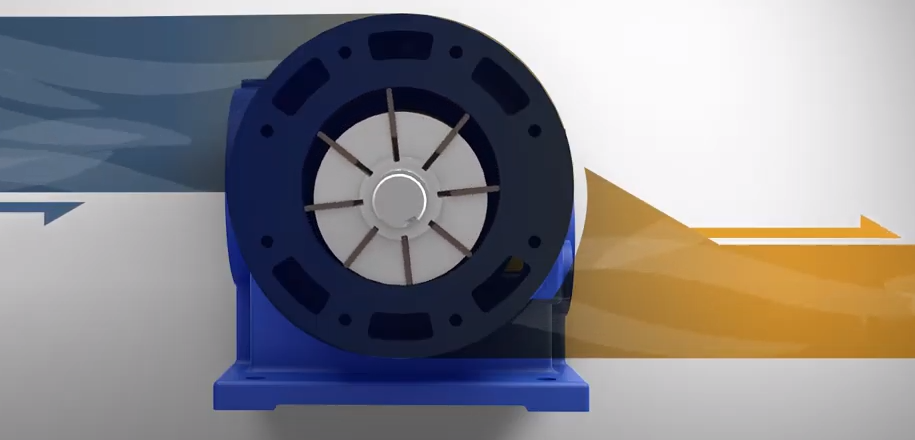

Advantages to Using a Rotary Sliding Vane Gas Compressor

The rotary sliding vane gas compressor is a cleverly designed, yet simple machine. It consists of a rotating element (the rotor) inside of a cylindrical casing (the cylinder).

Sliding Vane Compressors and Vacuum Process Equipment

Sliding vane compressors are powerful machines. They can also be used in a wide variety of industries in vacuum pump applications.

Vegetable Chilling with Vacuum Cooling

Preserving vegetables for transport is a unique challenge the food processing industry faces. Once harvested, produce has a limited window of freshness.

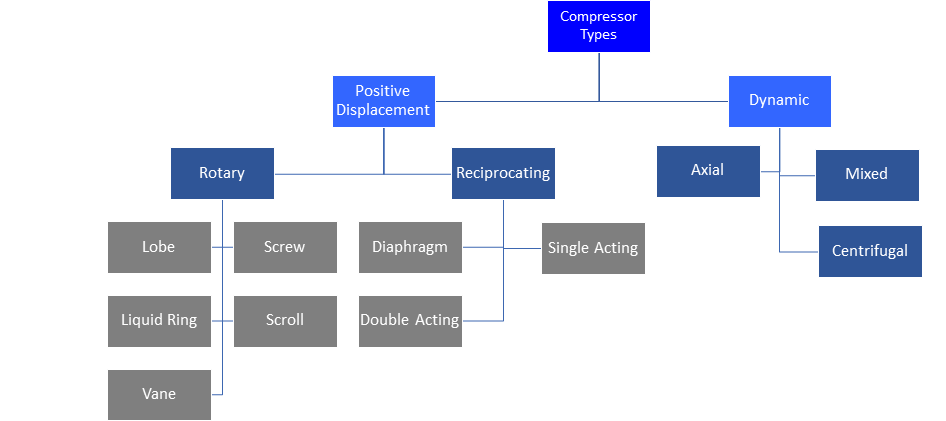

Types of Gas Compressors

A compressor is a mechanical device that increases the pressure of a gas by reducing its volume or by imparting velocity on the gas. This can be done in numerous different types of gas compressors.

Sliding Vane Compressor Benefits

A sliding vane compressor is a positive displacement compressor, meaning it decreases a specific volume of a gas, resulting in increased gas pressure.

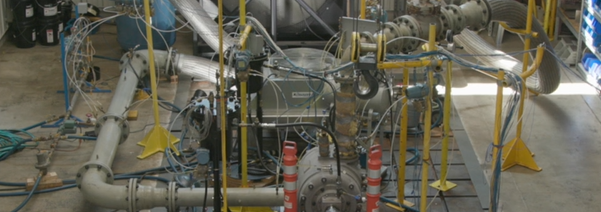

Common Rotary Equipment Tests and Analyses

Compressor testing can be utilized to validate expected performance, analyze product developments, determine baseline data in a controlled environment, troubleshoot unexpected or undesirable operation and much more.

Compressing Gas Streams Containing H2S

Sour gas is any gas containing significant amounts, typically above 20ppm, of hydrogen sulfide (H2S). H2S is a colorless gas that is heavier than air and harmful to humans at concentrations of 20 ppm in air.

Why Direct Injection Compressor Lubrication Is the Best Choice

Direct injection compressor lubrication is used in sliding vane gas compressors and has distinct benefits over other types of lubrication used by other compressors.

Common Oil and Gas Industry Applications for Gas Compressors

Despite advances in renewable power sources, crude oil remains one of the most valuable natural commodities today.

Biogas Management: What to Know About the Renewable Energy Source

Biogas is a natural energy source made from the decomposition of biological matter. More simply put, when food, animal waste, plants, sewage, and other natural waste is broken down by bacteria, a gas is formed that includes methane.

Benefits Of Using Vacuum Cooling In Food Processing

The International Trade Administration (ITA) estimates that nearly half of all food is lost before it ever reaches a consumer’s table.